Foras centrifugal pump KM 160-310. The pump is made of high quality cast iron, rust-proof, impeller is made of brass, not rust. Suitable for a variety of applications The product is durable in use.

Applications

Property

Power system

| CARATTERISTICHE COSTRUTTIVE / CONSTRUCTION FEATURES CARACTERISTICAS CONSTRUCTIVAS / CARACTERISTIQUES D’EXECUTION |

|

| Corpo pompa | ghisa |

| Pump body | cast iron |

| Cuerpo bomba | fundicion |

| Corps de pompe | fonte |

| Supporto motore | ghisa |

| Motor bracket | cast iron |

| Soporte motor | fundicion |

| Support moteur | fonte |

| Girante | Noryl® o ottone |

| Impeller | Noryl® or brass |

| Rodete | Noryl® o laton |

| Turbine | Noryl® ou laiton |

| Tenuta meccanica | ceramica-grafite |

| Mechanical seal | ceramic-graphite |

| Sello mecanico | ceramica-grafito |

| Garniture mecanique | ceramique-graphite |

| Albero motore | aciero AISI 303 |

| Motor shaft | stainless steel AISI 303 |

| Eje motor | acero AISI 303 |

| Arbre moteur | acier AISI 303 |

| Temperatura del liquido | girante Noryl®: o 0-50 °C |

| girante ottone: 0-90°C | |

| Liquid temperature | Noryl® impeller : 0-50 °C |

| brass impeller: 0-90°C | |

| Temperatura del liquido | rodete Noryl® : 0-50°C |

| rodete laton: 0-90°C | |

| Temperature du liquide | turbine Noryl®l : 0-50°C |

| turbine laton: 0-90°C | |

| Pressione di esercizio | |

| Operating pressure | max 8 bar |

| Presion de trabajo | |

| Pression de fonctionnement | |

| MOTORE / MOTOR / MOTOR / MOTEUR | |

| Motore 2 poli a induzione | 3- 230/400V-50Hz |

| 2 pole induction motor | 1-230V-50Hz con termoprotettore |

| Motor de 2 polos a inducción | with thermal protection |

| con proteccion termica | |

| Moteur a induction a 2 poles | avec protection thermique |

| Classe di isolamento | |

| Insulation class | F |

| Clase de aislamiento | |

| Classe d’isolation | |

| Grado di protezione | |

| Protection degree | IP44 |

| Grado de proteccion | |

| Protection | |

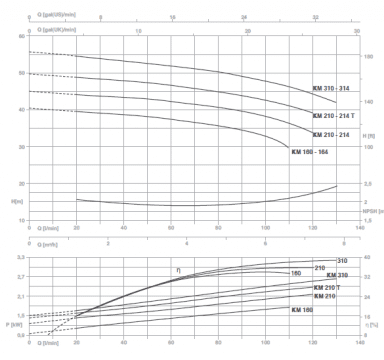

| Type | P2 | P1 (kW) | AMPERE | Q (m3/h – l/min) | ||||||||||||

| 1~ | 3~ | 1~ | 3~ | 0 | 1.2 | 2.4 | 3.6 | 4.8 | 5.4 | 6.6 | 7.2 | 7.8 | ||||

| HP | kW | 1~ | 3~ | 1x230V 50 Hz | 3x400V 50 Hz | 0 | 20 | 40 | 60 | 80 | 90 | 110 | 120 | 130 | ||

| H(m) | ||||||||||||||||

| KM 160/164 | KM 160/164 T | 1.5 | 1.1 | 1.9 | 1.8 | 8.5 | 3.4 | 40.5 | 39.3 | 38.6 | 37.5 | 35.6 | 34.6 | 29.5 | ||

| KM 210/214 | 2 | 1.5 | 2.2 | 10.3 | 45.1 | 44.1 | 43.3 | 42.3 | 40.5 | 39.2 | 36.4 | 33.5 | ||||

| KM 210/214 T | 2 | 1.5 | 2.43 | 4.9 | 50 | 48.7 | 47.8 | 46.5 | 44.9 | 43.7 | 41.3 | 39.4 | ||||

| KM 310/314 | KM 310/314 T | 3 | 2.2 | 2.85 | 2.67 | 13.5 | 5.1 | 55.9 | 54.5 | 53.4 | 52 | 50.1 | 48.9 | 46.2 | 44.2 | 41.9 |

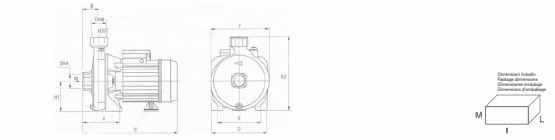

| TYPE | DIMENSIONS (mm) | CUBE | Kg | |||||||||||

| A | B | C | D | E | F | H1 | H2 | DNA | DNM | I | L | M | ||

| KM 160 | 117 | 46.5 | 348 | 220 | 180 | 225 | 115 | 285 | 1″G | 1″G | 370 | 240 | 315 | 22.5 |

| KM 164 | 117 | 46.5 | 348 | 220 | 180 | 225 | 115 | 285 | 1″ 1/4 G | 1″G | 370 | 240 | 315 | 22.5 |

| KM 210 | 117 | 46.5 | 348 | 200 | 180 | 225 | 115 | 285 | 1″G | 1″G | 370 | 240 | 315 | 23 |

| KM 214 | 117 | 46.5 | 348 | 220 | 180 | 225 | 115 | 285 | 1″ 1/4 G | 1″G | 370 | 240 | 315 | 23 |

| KM 310 | 117 | 46.5 | M 410 | 220 | 180 | 225 | 115 | 285 | 1″G | 1″G | 370 | 240 | 315 | M 27.5 |

| T 348 | T 23.5 | |||||||||||||

| KM 314 | 117 | 46.5 | M 410 | 220 | 180 | 225 | 115 | 285 | 1″ 1/4 G | 1″G | 370 | 240 | 315 | M 27.5 |

| T 348 | T 23.5 | |||||||||||||