LOHER VARIO SIEMENS

LOHER VARIO SIEMENS is durable and long-lasting

Category MOTOR

Tags มอเตอร์ siemens, มอเตอร์ไฟฟ้า, มอเตอร์ไฟฟ้า siemens

Facebook

Twitter

Email

Print

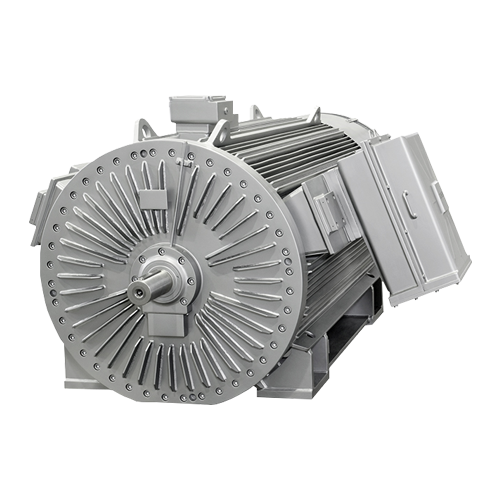

LOHER VARIO SIEMENS

Rugged and compact high voltage motors in fin, water jacket and tube cooling. Designed for applications in extreme environments and hazardous zones, especially in oil, gas and petrochemical industry. Available in all of the usual types of explosion protection – also double protection, degrees of protection up to IP66 (special designs up to IP68), special paint finishes, high and low temperature versions and cooling types tailored to the application – make them predestined for sectors such as oil, gas and

The LOHER VARIO is available in three different cooling frame types

LOHER VARIO – Fin cooled 0.15 – 2.8 MW

- Well suited to Zone 1 and highly explosive environments, including those containing hydrogen.

- Also certified for low temperatures, suitable for use in arctic environments

- Extremely rugged due to torsional stiff steel frame

- On request also available in double protection Ex d and Ex e

- Double certified motors for use in hazardous zones with gas or dust

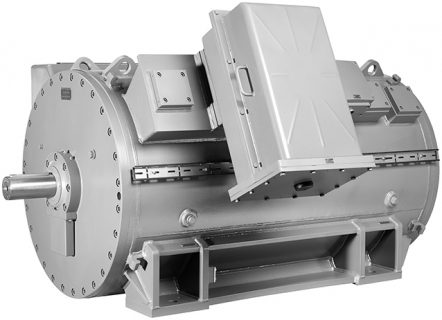

Water jacket cooled up to 1.85 MW, commonly used in offshore applications

- Compact design to reduce space required and transport costs

- Very low maintenance water jacket cooling system

- Long service life as a result of the uniform cooling

- Seawater/saltwater can be directly used as coolant

- Extremely quiet as they have no outer fan – even when converter operated

- Extremely high overload capability

LOHER VARIO Tube cooled 1.9 – 7 MW

- Very rugged with stainless steel cooling pipes

- Special inner cooling system with X ventilation, axial and radial cooling slots for a uniform temperature distribution

- Flameproof enclosure (Ex d) up to 7 MW

Your Benefits

- Safe operation also in exceedingly hazardous areas, e.g., LNG tankers

- Predestinated for extreme locations, e.g. offshore rigs

- Increased stiffness, low vibration levels, maximum reliability

- Outstanding suitability for deserts and arctic regions

- Highly modifiable for individual customer demands retrofit applications

Features

- Covering all of the applicable types of ex-protection

- Degree of protection up to IP66 (special designs up to IP68)

- Engineered based on international standards (ATEX, NEPSI, EAC (Gost), CCOE certified)

- Extremely rugged due to torsional stiff steel frame

- Available in high and low temperature design

Technical data overview

Brief overview

| Shaft heights: | 355 – 1000 mm |

| Power range: | 0.15 – 7 MW |

| No. of poles: | 2 – 16 poles (higher on request) |

| Rated voltages: | 3 – 11kV (higher on request) |

| Degree of protection: | IP55, IP56, IP65, IP66 (special designs up to IP68) |

| Cooling type: | IC 411, IC 416, IC 511, IC 516, IC 71 W |

| Explosion protection: | – Non sparking, Zone 2, II 3 G Ex nA IIC T3 Gc |

| – Increased safety, Zone 1, II 2 G Ex e IIC T3 Gb | |

| – Flameproof, Zone 1, II 2 G Ex de IIB T4 Gb | |

| – Flameproof, Zone 1, II 2 G Ex de IIC T4 Gb | |

| – Pressurized, Zone 1, II 2 G Ex px IIC T3 Gb |